Introduction

In the demanding world of construction and heavy industries, cranes are indispensable for lifting and moving heavy loads. The reliability of these machines directly impacts the efficiency and safety of operations. When it comes to maintaining and optimizing crane performance, having access to high-quality crane parts is crucial. Mantra Enterprise LLC stands out as a leading provider of crane parts in the USA, offering not only a wide range of high-quality products but also expert advice and excellent customer service. This article explores how Mantra Enterprise LLC excels in delivering comprehensive solutions for crane parts, along with other critical components and consultancy services.

Comprehensive Range of Crane Parts in the USA

High-Quality Crane Parts

Mantra Enterprise LLC prides itself on offering an extensive selection of crane parts in the USA that meet rigorous industry standards. Our product range includes:

- Crane Hoists and Winches are essential for lifting and lowering loads with precision. We supply a variety of models designed to handle different load capacities and operational requirements.

- Crane Jib Extensions increase the reach and flexibility of cranes, allowing them to access areas that would otherwise be difficult to reach. Our extensions are built to withstand heavy loads and harsh conditions.

- Crane Hooks and Slings are crucial for securely attaching and lifting loads. We offer a range of hooks and slings designed for durability and safety.

- Crane Bearings and Gears ensure the smooth operation of cranes by reducing friction and wear. Our components are engineered for longevity and high performance.

- Crane Control Systems provide precise operation of cranes, improving safety and efficiency. We offer state-of-the-art control systems to enhance your crane operations.

Each component is sourced from top manufacturers and undergoes stringent quality checks to ensure reliability and durability.

Mining Spare Parts in the USA

In addition to crane parts, Mantra Enterprise LLC is a premier provider of mining spare parts in the USA. The mining industry requires robust parts that can endure extreme conditions. Our offerings include:

- Mining Drills and Bits are essential for excavation and material extraction. We provide high-quality tools designed for efficiency and longevity.

- Shovels and Excavator Parts are critical for material handling. Our parts ensure optimal performance and durability, even in challenging environments.

- Crusher Parts are vital for processing mined materials. We offer parts that maintain the performance and reliability of crushing equipment.

By providing top-notch mining spare parts in the USA, we support the smooth operation of mining activities, ensuring that equipment remains functional and effective.

Heavy Equipment Spare Parts in the USA

Heavy machinery is crucial for large-scale construction projects. Mantra Enterprise LLC offers a comprehensive range of heavy equipment spare parts in the USA, including:

- Excavators and Loaders Parts such as hydraulic cylinders and pumps are essential for the efficient operation of excavators and loaders. We provide components that enhance performance and durability.

- Bulldozers and Graders Components like undercarriages and blades are crucial for the effective operation of bulldozers and graders. Our parts are designed to withstand heavy use.

- Rollers and Compactors ensure effective soil compaction and levelling. We offer high-quality components for reliable performance.

Our heavy equipment spare parts in the USA are designed to improve the functionality and longevity of machinery, ensuring optimal performance on the job site.

Construction Equipment Spares in the USA

For the construction industry, Mantra Enterprise LLC provides a wide range of construction equipment spares in the USA. Our products include:

- Concrete Mixers and Pumps ensure smooth operation and efficient mixing and pumping of concrete.

- Compactors and Rollers enhance soil compaction and levelling capabilities.

- Backhoes and Skid Steers are essential for versatile digging and lifting tasks. We provide high-quality components to support various construction activities.

Our construction equipment spares in the USA are engineered for reliability and performance, helping you tackle a wide range of construction tasks efficiently.

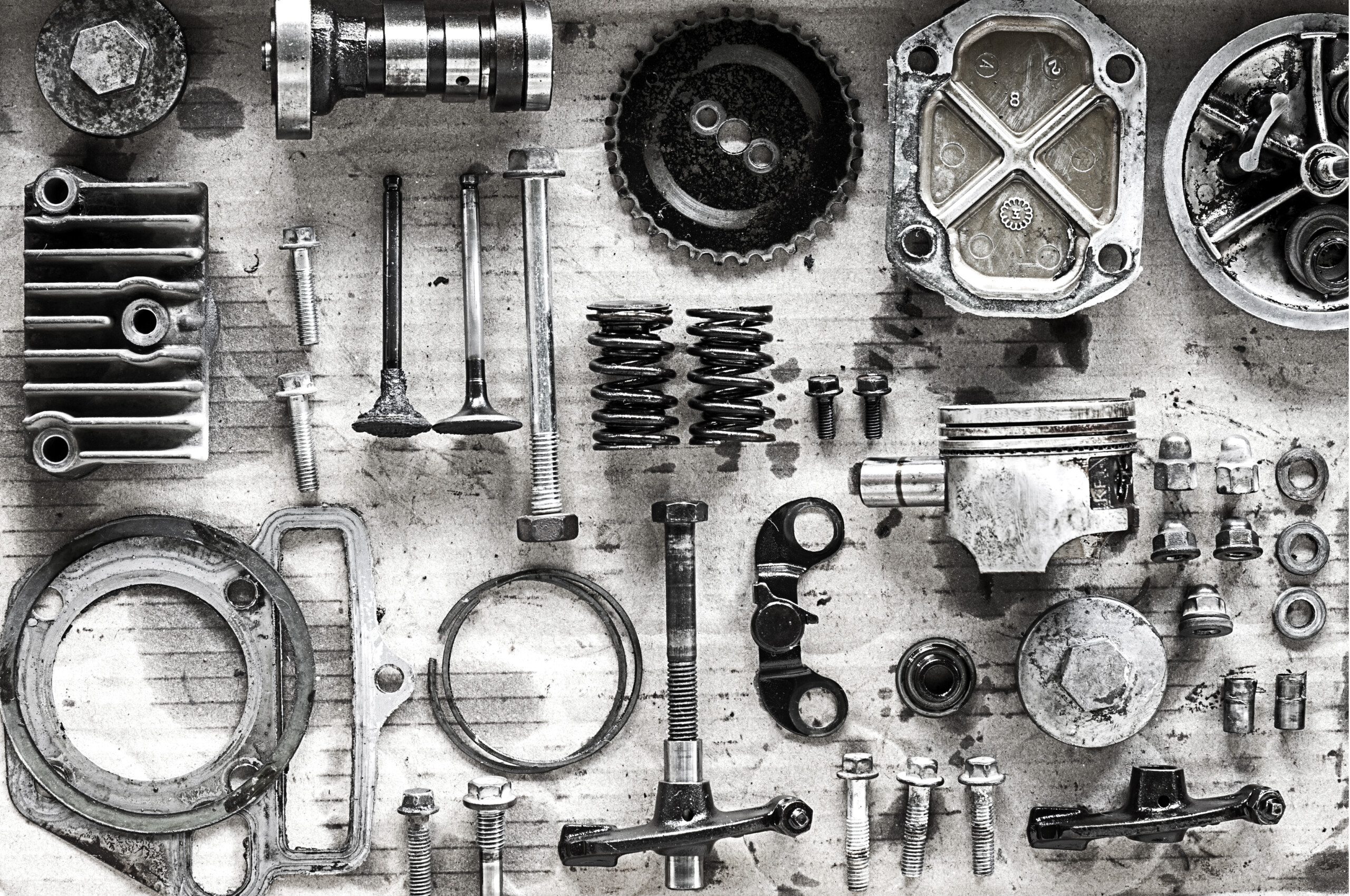

Engine Parts in the USA

Engines are critical to the operation of heavy machinery. Mantra Enterprise LLC offers a range of engine parts in the USA designed for durability and performance:

- Pistons and Rings are essential for the efficient operation of engines. We offer high-quality components that ensure reliable engine performance.

- Camshafts and Crankshafts are crucial for engine timing and movement. Our parts are designed for precision and durability.

- Filters and Fuel Pumps maintain engine cleanliness and efficiency. We provide components that help keep your engine in optimal condition.

Our engine parts in the USA are designed to meet the demanding requirements of heavy machinery, ensuring long-term reliability and performance.

Filters in the USA

High-quality filters in the USA are essential for maintaining clean and efficient machinery. Mantra Enterprise LLC offers:

- Oil Filters remove contaminants from engine oil, extending the life of your engine.

- Air Filters ensure clean air intake, which is vital for optimal engine performance.

- Fuel Filters prevent impurities from affecting fuel systems, maintaining the efficiency of your machinery.

Our filters are designed to enhance the lifespan and efficiency of your equipment, reducing maintenance needs and extending operational life.

Transmission Parts in the USA

Reliable transmission parts in the USA are crucial for the smooth operation of heavy machinery. We offer:

- Transmission Gears and Shafts are essential for power transfer in transmissions. Our parts are engineered for durability and performance.

- Clutches and Torque Converters converters provide smooth and efficient operation. We offer components designed for reliability and efficiency.

- Bearings and Seals ensure reliable transmission performance, reducing wear and tear on components.

Our transmission parts in the USA are designed to provide durability and efficiency, supporting the smooth operation of your machinery.

Construction Attachments in the USA

Construction attachments in the USA enhance the versatility of construction equipment. Mantra Enterprise LLC offers:

- Hydraulic Hammers are used for breaking up concrete and rock. Our attachments are designed for powerful and efficient operation.

- Buckets and Grabs are essential for material handling. We provide attachments that enhance the functionality of your equipment.

- Augers and Grapples are used for specialized digging and gripping tasks. Our attachments are designed to improve the versatility of your machinery.

Expert Advice and Excellent Customer Service

- Personalized Consultation

At Mantra Enterprise LLC, we recognize that every project and operation has unique requirements. Our team of experts provides personalized consultation to help you find the right crane parts and other components for your specific needs. Whether you require crane parts in the USA, mining spare parts in the USA, or any other type of equipment, our knowledgeable staff will guide you through the selection process.

- Technical Support

Our commitment to customer service extends beyond the sale of parts. We offer technical support to assist with installation, maintenance, and troubleshooting. Our team is available to provide expert advice and ensure that your equipment operates smoothly and efficiently.

- Timely Delivery and Logistics

Efficient logistics is a key component of our service offering. Mantra Enterprise LLC ensures timely delivery of all crane parts in the USA and other components. We leverage our extensive network and logistics expertise to ensure that your parts reach you quickly and reliably. Our logistics consultancy in the USA helps streamline the supply chain, reducing lead times and improving overall efficiency.

Comprehensive Services Provided in the USA

- Procurement Consultancy

In addition to providing high-quality parts, Mantra Enterprise LLC offers procurement consultancy in the USA. Our experts work closely with you to develop procurement strategies that align with your operational goals and industry trends. We help you source the best parts and manage your supply chain effectively, ensuring that you have access to the components you need when you need them.

- Logistics Consultancy

Our logistics consultancy in the USA services are designed to optimize your supply chain and improve efficiency. We provide solutions for inventory management, transportation, and distribution, helping you reduce costs and enhance the performance of your operations.

Conclusion

Mantra Enterprise LLC is your one-stop solution for crane parts in the USA and beyond. With our comprehensive range of high-quality products, expert advice, and excellent customer service, we are dedicated to supporting your operations and helping you achieve your goals. Whether you need mining spare parts in the USA, heavy equipment spare parts in the USA, or any other type of component, our team is here to provide the solutions you need. By choosing Mantra Enterprise LLC, you gain access to top-notch products, personalized support, and efficient logistics solutions. Our commitment to quality and service ensures that you receive the best value and performance from your equipment. Contact us today to learn more about how we can support your needs and help your business thrive.