Introduction

The United Arab Emirates (UAE) has evolved as a hub of industrial development, with mining playing a pivotal role in its economic landscape. Mining machinery is essential to this industry, supporting the extraction of vital resources such as limestone, gypsum, marble, and aggregates. The UAE’s ambitious infrastructure projects, both locally and across the GCC, rely heavily on mining machinery to maintain a steady supply of these essential materials.

This blog will explore the landscape of mining machinery in the UAE, emphasizing the critical role of mining spare parts in UAE, the significance of heavy equipment spare parts in UAE, and the contributions of construction equipment spares in UAE. Let’s navigate the importance of mining machinery and its ecosystem, from suppliers to industry leaders.

Importance of Mining Machinery

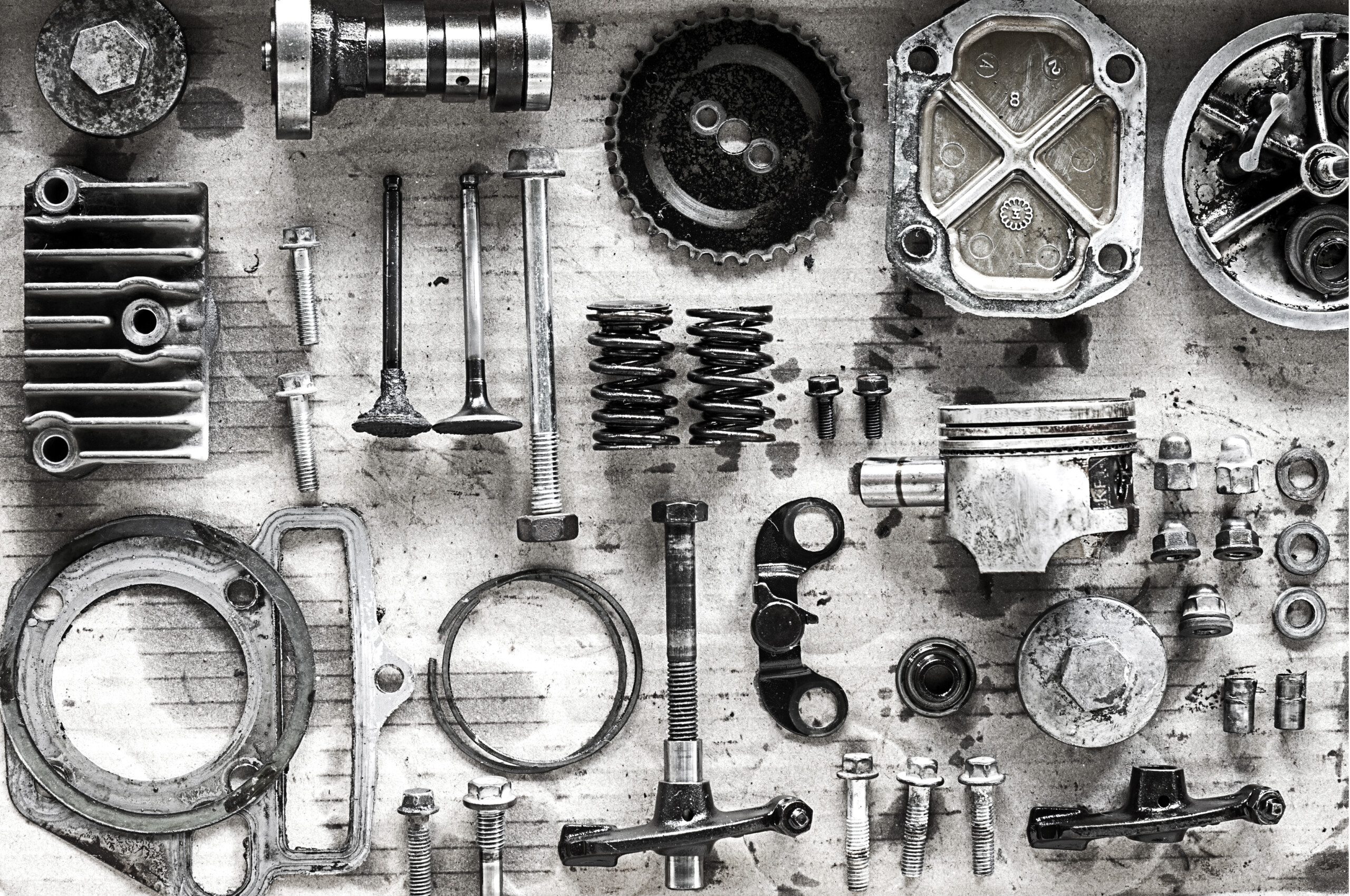

Mining machinery forms the backbone of the UAE’s resource extraction industry. From massive excavators to crushing machines and conveyors, this equipment allows the country to extract and process raw materials efficiently. Without this machinery, the country’s key construction and industrial projects would face supply shortages and delays, impacting the broader economy.

Key machinery used in the UAE’s mining sector includes:

- Excavators: Used to extract material from mining sites.

- Crushers: These machines crush the raw material into usable forms, such as aggregates used in construction.

- Conveyors: Essential for transporting raw materials within mining sites.

- Loaders: Used to move raw material to processing areas.

The quality and reliability of machinery play a critical role in ensuring smooth operations. As mining machinery operates in harsh environments, the demand for mining spare parts in UAE is a constant need. These spare parts help maintain the machinery’s performance, ensuring uptime and minimizing breakdowns.

The ability to procure high-quality mining spare parts in UAE is what keeps projects running on time and within budget. Whether for regular maintenance or emergency repairs, the availability of spare parts ensures that mining companies can keep their operations moving without interruptions.

Heavy Equipment Rental in the UAE’s Mining Sector

While large mining operations typically own their fleet of machinery, many smaller and medium-sized mining companies prefer to rent heavy equipment. Renting offers flexibility and access to the latest technology without the high upfront costs of purchasing new machinery. This trend has made heavy equipment rental in UAE a key service, particularly for companies looking to scale up or down depending on project requirements.

The UAE’s growing demand for construction and infrastructure development means that mining companies often require short-term solutions to meet surging needs. Heavy equipment rental provides them with the opportunity to access the necessary tools and equipment without long-term financial commitments.

Key advantages of heavy equipment rental in the UAE:

- Cost Efficiency: Renting avoids the high initial cost of purchasing machinery.

- Access to the Latest Technology: Rental companies frequently update their fleets, allowing clients to benefit from modern, more efficient equipment.

- Flexible Solutions: Companies can rent equipment as and when needed, avoiding storage and maintenance costs when not in use.

For those in the mining industry, rental is not just about getting the equipment but also ensuring it runs efficiently. Therefore, rental services often come with the added benefit of maintenance packages that include the provision of heavy equipment spare parts in UAE. This ensures that the rented machinery performs at optimal levels throughout the duration of the contract.

Key Industry Players

The UAE’s mining industry relies on numerous local and international companies for machinery, spare parts, and services. These companies play a crucial role in providing state-of-the-art equipment and robust maintenance solutions, ensuring that mining operations run smoothly.

Notable Construction Equipment Companies in the UAE:

- Al-Bahar: A leading supplier of Caterpillar machinery in the region, Al-Bahar provides everything from excavators to bulldozers. They also offer an extensive range of mining spare parts in UAE, supporting the country’s heavy machinery requirements.

- Saeed & Mohammed Al Naboodah Group: This company is a key player in the construction and mining sectors, providing high-quality heavy equipment spare parts in UAE alongside machinery sales and rentals. Their extensive experience makes them a reliable partner for large-scale projects.

- Volvo Construction Equipment: Volvo’s machinery is highly regarded for its durability and performance, making it popular in the UAE’s mining sector. Their equipment includes excavators, wheel loaders, and articulated haulers, all of which are supported by a comprehensive inventory of construction equipment spares in UAE.

- Mantrac Group: This group is a major distributor of heavy machinery and offers a wide range of products to the mining sector. With their global footprint, they ensure the availability of top-quality mining spare parts in UAE, essential for minimizing downtime.

These industry players are crucial to the success of mining operations across the UAE. They ensure that companies have access to the latest machinery while also providing the necessary heavy equipment spare parts in UAE to keep operations running efficiently.

Local Suppliers and Manufacturers

The UAE has increasingly focused on localizing its industrial supply chain, with more emphasis on home-grown manufacturers and suppliers of mining machinery. While the country still relies heavily on imports for specialized equipment, industrial equipment suppliers in UAE are stepping up to provide critical components and services.

Leading Industrial Equipment Suppliers in the UAE:

- Gulf Rock Engineering Group: Gulf Rock is a local leader in rock drilling and blasting services. They provide a range of mining machinery and are key suppliers of mining spare parts in UAE for companies working in quarrying and rock excavation.

- Al Marwan Heavy Equipment & Machinery: This company is a prominent player in providing both new and used construction and mining machinery in the UAE. Their portfolio includes a comprehensive range of construction equipment spares in UAE, ensuring that their clients have access to essential parts for repairs and maintenance.

- FAMCO (Al-Futtaim Auto and Machinery Company): FAMCO is a major distributor of heavy machinery in the region, offering not just equipment but also a wide range of heavy equipment spare parts in UAE. Their strong local presence means they can meet the urgent spare parts needs of the mining sector swiftly.

The shift toward supporting local suppliers has had a positive impact on the UAE’s mining sector. Local manufacturers are now able to offer competitive solutions, reducing dependency on international suppliers. Additionally, having local industrial equipment suppliers in UAE means that spare parts can be procured faster, minimizing downtime and boosting operational efficiency.

Conclusion

The mining machinery sector in the UAE plays a critical role in the country’s economic development, supporting not only mining but also large infrastructure projects. The demand for machinery is growing, and with it, the need for reliable mining spare parts in UAE, heavy equipment spare parts in UAE, and construction equipment spares in UAE.

From heavy equipment rental services to local manufacturers and key industry players, the ecosystem surrounding mining machinery is robust and constantly evolving. The availability of spare parts, in particular, is essential to maintaining the efficiency of these operations. As the UAE continues to expand its mining and construction sectors, the importance of having a strong supply chain for machinery and parts will only grow.

With a thriving network of industrial equipment suppliers in UAE and a focus on local production, the future of mining machinery in the UAE looks promising. As the industry evolves, companies will need to adapt to new technologies and innovations, ensuring that they remain competitive in this dynamic market. The efficient utilization of mining machinery and a reliable supply chain will be key to sustaining the UAE’s growth trajectory.