Introduction

Indonesia, as one of Southeast Asia’s largest economies, is undergoing significant infrastructural transformation. With a growing population and an increasing demand for urbanization, the construction industry plays a critical role in shaping the country’s future. From towering skyscrapers in Jakarta to expansive infrastructure projects like highways, airports, and bridges, Indonesia’s construction boom is reshaping its physical and economic landscape. A key enabler of this growth is the availability and efficiency of construction equipment in Indonesia, which is vital for executing large-scale projects efficiently.

Heavy machinery forms the backbone of infrastructure development in Indonesia. Without access to advanced, reliable equipment, projects would face substantial delays, cost overruns, and quality issues. The construction sector, therefore, relies heavily on a wide array of specialized machines, such as cranes, bulldozers, and excavators, to ensure seamless operations. In particular, cranes, with their essential crane parts in Indonesia, are indispensable for high-rise buildings and other vertical construction endeavors.

This blog delves into the crucial role of construction equipment in Indonesia’s development, the importance of freight consultancy in logistics, emerging market trends, and technological innovations driving the industry forward.

Key Types of Construction Equipment

Overview of Essential Heavy Machinery Used in Indonesian Construction Projects

The scale and diversity of construction projects in Indonesia demand a wide range of heavy machinery, each tailored to meet specific operational needs. From road construction and bridge building to the construction of residential and commercial spaces, the country’s dynamic infrastructure projects require heavy-duty equipment that can withstand the demanding conditions of the Indonesian environment.

One of the most frequently used machines is the excavator, essential for digging foundations, trenching, and clearing land. Excavators are designed for multi-functionality, making them a cornerstone of large-scale construction projects. Similarly, bulldozers, with their powerful blades, are indispensable for moving large quantities of earth, leveling land, and demolishing structures.

Another key player in the heavy machinery segment is the crane, which is vital for lifting and transporting heavy materials on construction sites. Cranes are extensively used in the construction of high-rise buildings, power plants, bridges, and other large-scale infrastructure projects. In Indonesia, the use of cranes has expanded in response to the growing demand for vertical construction, and ensuring the availability of crane parts in Indonesia has become crucial for maintaining the operational efficiency of these machines.

Beyond excavators, bulldozers, and cranes, loaders, graders, and concrete mixers are also frequently employed in the construction process. Each of these machines plays a specialized role in delivering efficient, high-quality results in construction projects across Indonesia.

Focus on Cranes and Their Various Parts

Cranes are among the most vital and versatile pieces of machinery used in Indonesia’s construction industry. They come in various types, including tower cranes, mobile cranes, and gantry cranes, each designed for specific lifting and material-handling needs. Whether constructing multi-story buildings in urban centers or working on massive infrastructure projects like ports and bridges, cranes are indispensable.

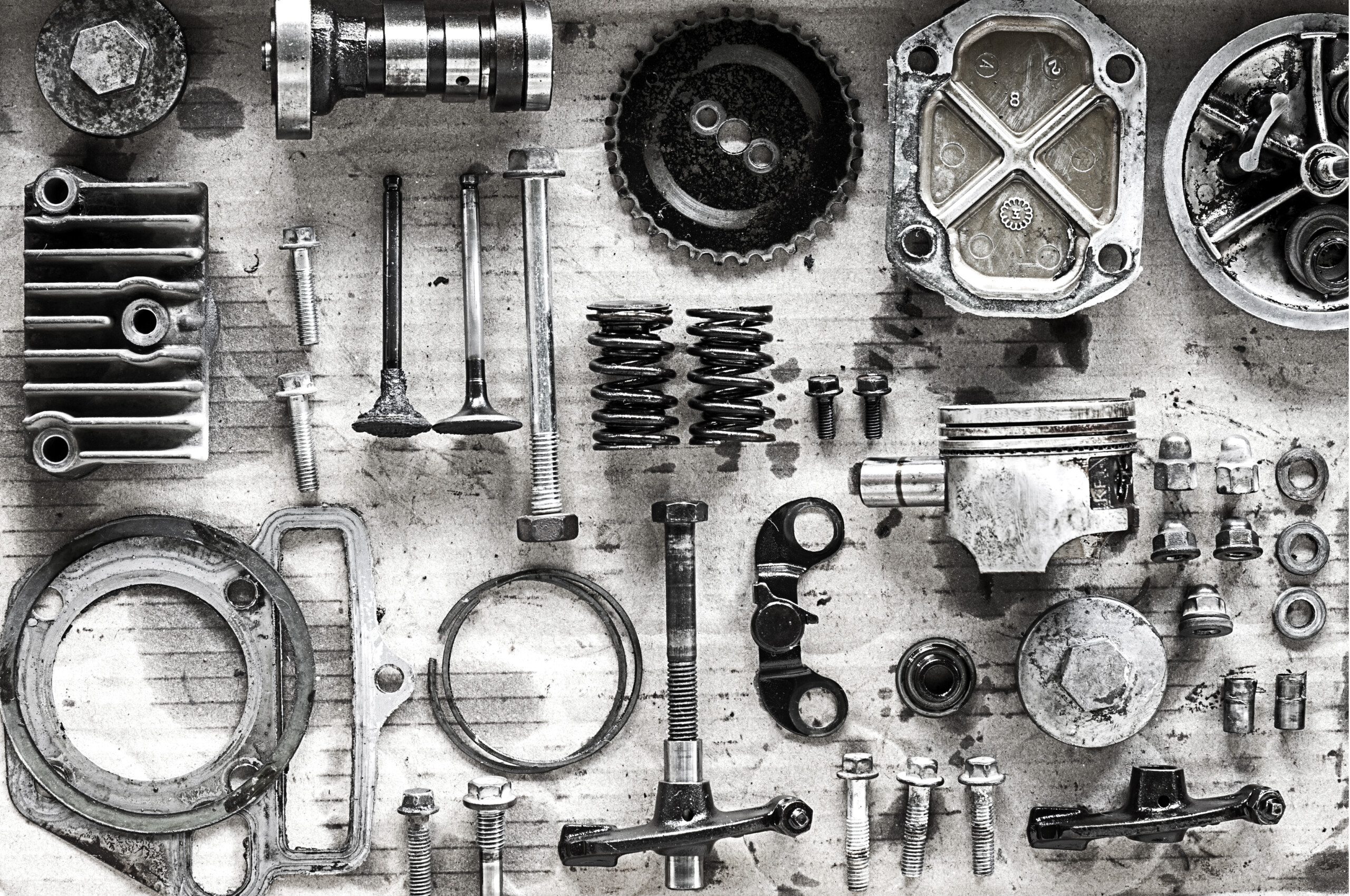

The efficiency of cranes relies heavily on their maintenance and the availability of high-quality crane parts in Indonesia. Parts such as hoists, sheaves, jibs, and outriggers must be in optimal condition to ensure safe and uninterrupted operation. Given the challenging conditions under which cranes operate—often in high heat, humidity, and dusty environments—regular maintenance and timely replacement of parts are essential to prevent costly downtime.

In recent years, Indonesia’s construction industry has seen a rising demand for modern cranes equipped with advanced technology, such as remote control systems and automated lifting mechanisms. This trend is driving the need for specialized construction equipment in Indonesia that is not only reliable but also adaptable to emerging technological advancements.

The Role of Freight Consultancy

How Freight Consultancy Aids in Equipment Logistics

Logistics is a critical component of the construction industry, particularly when it comes to the transportation of heavy machinery. Moving large-scale construction equipment in Indonesia across the country’s vast and diverse terrain requires meticulous planning, coordination, and execution. This is where freight consultancy plays a pivotal role in ensuring that equipment is delivered on time, safely, and cost-effectively.

Freight consultants provide essential services that help construction companies manage the complex logistics involved in transporting machinery and parts, particularly for long-haul projects in remote or underdeveloped areas. By optimizing routes, coordinating shipments, and ensuring compliance with local regulations, freight consultants help reduce delays, minimize costs, and ensure the safe delivery of heavy equipment rental in Indonesia.

Transportation of crane parts in Indonesia is one area where freight consultancy has proven invaluable. Cranes are often disassembled for transportation, and ensuring that each part is shipped efficiently and reassembled properly is critical to project timelines. Freight consultants also coordinate the importation of specialized machinery from international manufacturers, helping construction companies navigate customs regulations, taxes, and other logistical hurdles.

Furthermore, freight consultancy services in Indonesia have become increasingly sophisticated, leveraging technology such as GPS tracking and automated inventory systems to provide real-time updates on equipment movement. This ensures that companies can closely monitor their assets, reducing the risk of delays caused by unexpected disruptions.

Importance of Efficient Transportation in Construction Projects

Efficient transportation is not merely a logistical concern; it directly affects project timelines, costs, and outcomes. For a construction project to stay on schedule, heavy machinery must be transported, assembled, and made operational quickly. A delay in receiving critical construction equipment in Indonesia can cascade into larger problems, causing workforce downtime and increasing project costs.

One of the challenges in Indonesia is its geographical diversity. From densely populated urban centers like Jakarta to remote, rural areas, construction projects often take place in hard-to-reach locations. Freight consultancy ensures that machinery is delivered efficiently, even to the most isolated areas. By managing logistics effectively, companies can avoid project delays, mitigate risks, and ensure that they remain competitive in the fast-paced Indonesian construction market.

Market Trends and Innovations

Current Trends in Construction Equipment in Indonesia

Indonesia’s construction sector is evolving rapidly, driven by both economic development and technological innovation. One of the most significant trends in the industry is the increasing demand for heavy equipment rental in Indonesia. Renting machinery has become a preferred option for many construction companies, allowing them to access the latest technology without the high upfront costs associated with purchasing equipment.

The rental market for construction equipment in Indonesia has seen a sharp increase in demand, as companies seek to improve operational efficiency while controlling costs. By renting equipment, firms can ensure that they have access to the right machines for specific project requirements, without the long-term maintenance and storage concerns associated with ownership. Additionally, rental companies often provide comprehensive maintenance and repair services, ensuring that the equipment remains in top working condition throughout the project duration.

Another major trend is the growing adoption of automated and smart machinery. Technologies such as GPS, AI-powered systems, and real-time data analytics are increasingly being integrated into Indonesia’s heavy machinery manufacturers. This shift is helping to improve productivity, reduce operational risks, and ensure more precise execution of construction tasks. For example, GPS-controlled graders and bulldozers allow for more accurate leveling of terrain, while AI-powered cranes can make autonomous adjustments for safer and more efficient material handling.

Emerging Technologies and Their Impact on Efficiency

Technological advancements are revolutionizing the way construction projects are executed in Indonesia. One such innovation is the integration of telematics in heavy machinery, which allows for real-time monitoring of equipment performance, fuel consumption, and maintenance needs. By leveraging telematics, companies can ensure that their construction equipment in Indonesia operates at peak efficiency, reducing operational costs and prolonging the lifespan of their machines.

Automation is another game-changer in the construction industry. The use of autonomous vehicles and machinery, such as driverless trucks and automated cranes, is becoming more prevalent, enabling companies to complete tasks faster and with greater precision. These machines are equipped with sensors and AI algorithms that allow them to navigate construction sites safely, avoiding obstacles and adjusting their operations based on real-time data. This not only enhances operational efficiency but also improves safety on construction sites, where human error is a leading cause of accidents.

In addition, Indonesia’s heavy machinery manufacturers are increasingly focusing on sustainability by incorporating eco-friendly technologies into their equipment. Hybrid and electric machinery are becoming more common, reducing the carbon footprint of construction projects while still delivering the power and performance required for heavy-duty tasks. This trend is particularly relevant as Indonesia ramps up its efforts to meet global sustainability standards.

Conclusion

The construction industry in Indonesia is rapidly evolving, driven by significant infrastructure development, urbanization, and government investment in large-scale projects. At the heart of this transformation is the efficient and reliable use of construction equipment in Indonesia, which ensures that projects are completed on time, within budget, and to the highest quality standards.

Heavy machinery, including cranes, excavators, and bulldozers, plays a critical role in the success of Indonesia’s construction sector. The availability of crane parts in Indonesia, combined with advancements in freight consultancy and efficient transportation logistics, ensures that companies can meet the demands of their projects without unnecessary delays or complications.

Emerging trends, such as the increased reliance on heavy equipment rental in Indonesia and the adoption of smart technologies, are reshaping the way construction projects are executed. Companies that embrace these innovations will be better positioned to compete in Indonesia’s fast-growing construction market.

In conclusion, the construction equipment landscape in Indonesia is both dynamic and essential to the country’s ongoing development. As the demand for reliable, high-performance machinery continues to grow, the industry will increasingly depend on the availability of Indonesia’s heavy machinery manufacturers and the adoption of cutting-edge technologies to ensure continued growth and success.