Heavy machinery is integral to industries like construction, mining, and manufacturing, where durability and reliability are paramount. The longevity and performance of these machines directly impact operational efficiency and financial outcomes. A key factor in maintaining and extending the life cycle of heavy machinery is the use of quality spare parts. This blog explores the essential role that spare parts play in preventing breakdowns, improving performance, and maximizing the return on investment.

The Importance of Spare Parts in Machinery Maintenance

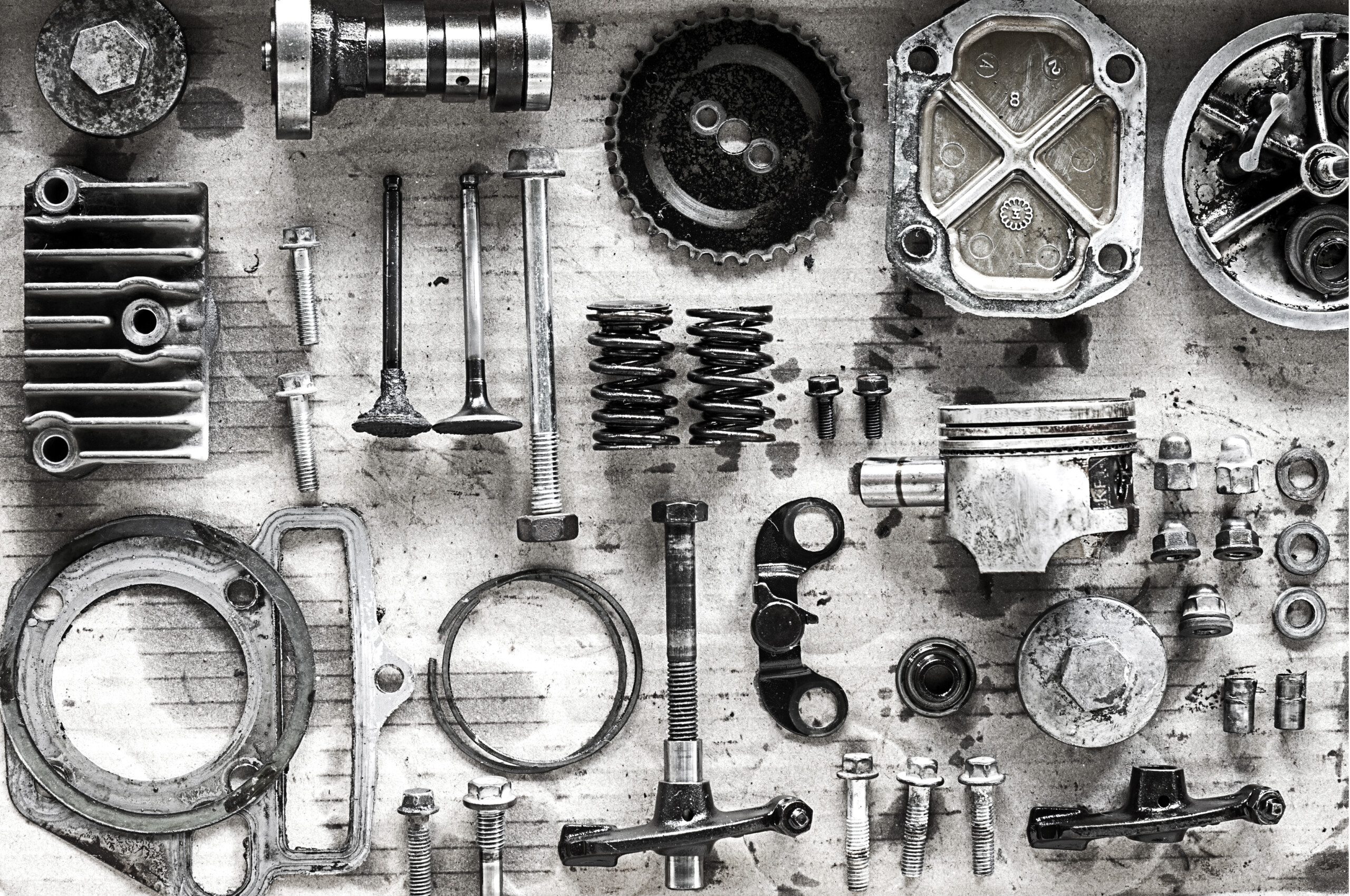

Heavy machinery is designed to operate under demanding conditions, often running continuously for long periods. This rigorous use leads to inevitable wear and tear, making regular maintenance essential. Spare parts, such as engine components, filters, transmission parts, and attachments, are critical to this maintenance process.

- Preventing Costly Breakdowns

One of the primary benefits of using high-quality spare parts is the prevention of unexpected breakdowns. Downtime in industries like construction and mining can be extremely costly, not just in terms of repair expenses but also due to project delays and lost productivity. By ensuring that machinery is equipped with reliable spare parts, companies can reduce the likelihood of breakdowns, maintaining continuous operation and adhering to project timelines.

- Enhancing Performance and Efficiency

Spare parts play a vital role in maintaining and even enhancing the performance of heavy machinery. Over time, components can degrade, leading to reduced efficiency and increased fuel consumption. Replacing worn-out parts with high-quality spares can restore machinery to optimal performance levels, improving overall efficiency and reducing operational costs.

- Strategic Inventory Management of Spare Parts

Maintaining an inventory of essential spare parts is crucial for ensuring that machinery downtime is minimized. However, managing this inventory requires careful planning and strategy. It’s important to balance the cost of holding inventory with the need to have parts readily available when needed.

- Identifying Critical Parts

Not all spare parts are equally critical. Companies should identify which parts are most likely to fail and which failures would cause the most significant downtime. These parts should be prioritized in the inventory. Components like engine parts, filters, and transmission parts often fall into this category due to their frequent need for replacement and critical role in machine operation.

- Forecasting Demand

Effective spare parts management involves forecasting the demand for parts based on equipment usage patterns and maintenance schedules. Historical data, coupled with predictive analytics, can help companies anticipate when parts are likely to be needed, allowing them to manage inventory levels more efficiently.

- Supplier Relationships

Building strong relationships with suppliers is essential for effective inventory management. Reliable suppliers can provide consistent quality and timely delivery, ensuring that necessary parts are available when required. They can also offer valuable insights into product improvements and updates, helping companies stay ahead of potential issues.

The Role of Regular Maintenance

While the availability of spare parts is crucial, their impact is maximized when combined with a proactive maintenance strategy. Regular maintenance involves scheduled inspections and replacements of parts before they fail. This approach not only extends the lifecycle of the machinery but also improves safety and efficiency.

Scheduled Maintenance Intervals

Establishing and adhering to a schedule for routine maintenance is critical. This schedule should be based on the manufacturer’s recommendations and adjusted according to the actual usage and operating conditions of the machinery. Regular checks allow for early detection of wear and tear, enabling timely replacement of parts.

Predictive Maintenance

Advancements in technology, such as the use of sensors and data analytics, have made predictive maintenance more accessible. This approach uses real-time data to predict when parts are likely to fail, allowing for replacements to be made just in time. Predictive maintenance reduces the risk of unexpected breakdowns and optimizes the use of spare parts.

Conclusion: The Strategic Importance of Spare Parts

The role of spare parts in extending the life cycle of heavy machinery cannot be overstated. By investing in high-quality parts, maintaining a strategic inventory, and implementing a robust maintenance program, companies can significantly improve the durability and reliability of their machinery. This not only helps in keeping projects on schedule and within budget but also maximizes the return on investment in heavy equipment.

Mantra Enterprise LLC (Mantra ENT) understands the critical role that spare parts play in maintaining heavy machinery. As a leading trading company, Mantra ENT provides a comprehensive range of mining spare parts, heavy equipment spare parts, construction equipment spares, and more. With a commitment to quality and reliability, Mantra ENT supports industries by ensuring the availability of essential components, thereby helping companies achieve operational excellence and sustainability.