- Home

- Our Products

- Mining Parts

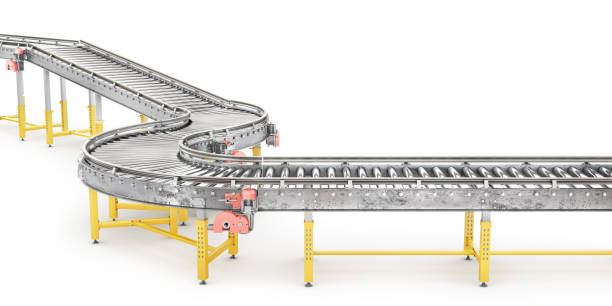

- Conveyor system

Description

Conveyor systems are essential for automating the movement of materials and products within various industries, including manufacturing, logistics, and warehousing. These systems are designed to transport goods efficiently from one point to another, reducing manual handling and improving overall productivity. Conveyor systems come in a variety of types, including belt conveyors, roller conveyors, and chain conveyors, each suited to different materials and operational requirements. Belt conveyors are ideal for moving bulk materials and packaged goods along a continuous loop, while roller conveyors are used for handling items with stable bases and are often employed in sorting and accumulation applications. Chain conveyors are designed for heavy-duty tasks and can handle more rugged materials. Modern conveyor systems can be equipped with advanced features such as automated controls, sensors, and integration with other material handling systems to enhance efficiency and accuracy. Proper maintenance, including regular inspections of belts, rollers, and chains, as well as lubrication and alignment checks, is crucial to ensure reliable performance and prevent downtime. By streamlining material handling processes, conveyor systems play a pivotal role in optimizing operations and enhancing productivity across a wide range of industries.

Industry Used

FAQ

A conveyor system is a mechanical equipment used to transport materials or products from one location to another within a facility. They are commonly used in manufacturing, warehousing, and distribution to improve efficiency and streamline operations.

Types of conveyor systems include belt conveyors, roller conveyors, chain conveyors, screw conveyors, and pneumatic conveyors. Each type is suited for different applications depending on the material being transported and the layout of the facility.

Consider factors such as the type of material being transported, the distance and speed required, the layout of your facility, and any special requirements (e.g., incline, temperature, or environment). Our team can help you select the most suitable conveyor system for your application.

Conveyor systems offer benefits such as increased efficiency, reduced manual handling, improved safety, and the ability to handle high volumes of material with minimal labor. They also help in optimizing workflow and reducing operational costs.

Regular maintenance includes checking and adjusting belt tension, inspecting and lubricating bearings, and cleaning the system to prevent debris buildup. Follow the manufacturer’s maintenance guidelines and schedule routine inspections to ensure reliable performance.

Identify the problem by checking for common issues such as misalignment, belt slippage, or unusual noises. Consult the system’s manual for troubleshooting steps, and contact our service team if you need professional assistance or repairs.

Yes, conveyor systems can be customized to meet specific needs such as unique sizes, configurations, or handling requirements. Contact us to discuss your requirements and explore custom solutions.

Conveyor belts come in various types including flat belts, modular belts, cleated belts, and endless belts. Each type is designed for specific applications and materials, so choosing the right belt depends on your system’s needs.

Conveyor systems can be designed to handle a wide range of materials including bulk items, packaged goods, and delicate products. The choice of conveyor type, belt material, and additional features (e.g., rollers, guides) will depend on the material’s characteristics and handling requirements.

Ensure that the conveyor system is equipped with safety features such as emergency stop buttons, guards, and safety sensors. Regularly inspect the system for potential hazards and ensure that operators are trained in safe operating practices.